Industrial steel detailing, centered around meticulous steel fabrication drawings, is vital for plant and warehouse construction. These blueprints specify dimensions, connections, and joints, ensuring structural integrity, safety, and longevity under extreme conditions. Accurate drawings facilitate efficient material management, minimize errors, and delays, fostering robust working environments. Effective communication through regular meetings, clear documentation, and digital platforms with industry-standard software ensures accurate steel fabrication drawings implementation, leading to high-quality, seamless construction.

Industrial steel detailing is the backbone of robust plant and warehouse structures, ensuring strength and longevity. This article delves into the intricate world of industrial steel detailing, highlighting its significance in construction quality. We explore essential components like steel fabrication drawings, which serve as blueprints for precise assembly, and emphasize the critical role of precision in design. Furthermore, best practices for communication are discussed to streamline projects, ensuring successful outcomes through effective collaboration. Understanding these aspects is key to optimizing structural integrity via industrial steel detailing.

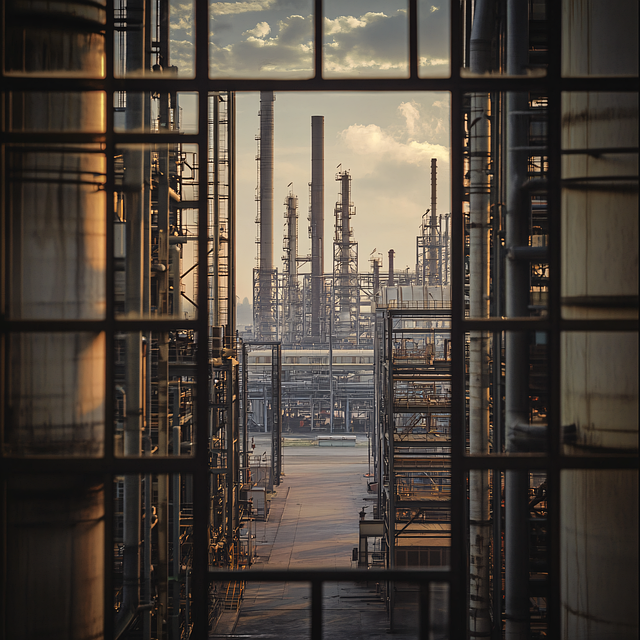

Understanding Industrial Steel Detailing: The Foundation of Quality Construction

Industrial steel detailing is a critical aspect of plant and warehouse construction, forming the very foundation of quality and durability. It involves the meticulous creation and implementation of precise steel fabrication drawings, which serve as blueprints for every component of the structure. These drawings encompass not just the dimensions and shapes but also the intricate connections and joints that hold the entire framework together.

Accurate steel detailing ensures that each part of the building is designed to withstand extreme loads, environmental conditions, and years of continuous operation. It involves a deep understanding of material properties, structural integrity, and safety standards. By meticulously planning and detailing every aspect of the steel structure, builders can guarantee the longevity and reliability of plant and warehouse facilities, creating robust environments for industrial operations.

Steel Fabrication Drawings: Unlocking the Blueprint for Plant and Warehouse Structures

Steel Fabrication Drawings are essential blueprints that bring plant and warehouse structures to life, detailing every component with precision. These technical drawings serve as a guide for the entire construction process, ensuring each piece of steel is cut, formed, and assembled correctly. By providing exact measurements, specifications, and layout arrangements, they enable efficient material management and accurate on-site fabrication.

In the world of industrial construction, these drawings are the backbone of successful projects. They facilitate clear communication between architects, engineers, fabricators, and construction teams, minimizing errors and delays. With meticulous attention to detail, each steel element is meticulously outlined, allowing for seamless integration during installation, ultimately contributing to robust and durable plant and warehouse structures.

The Role of Precision in Plant and Warehouse Steel Detailing

In the realm of industrial construction, precision is paramount, especially when it comes to steel detailing for plant and warehouse structures. Accurate steel fabrication drawings are not merely technical blueprints; they are the blueprint for a robust and safe working environment. Every measurement, every angle, and every connection in these detailed plans plays a vital role in ensuring structural integrity and longevity. Precision in steel detailing ensures that components fit seamlessly together, maximizing efficiency during construction and minimizing potential errors or failures over time.

The meticulousness involved in creating and adhering to these drawings is crucial for navigating the complex landscape of industrial steel fabrication. Whether it’s designing support beams, gantries, or storage racks, each element must be meticulously calculated and depicted to withstand the demanding environments of plants and warehouses. This level of precision not only guarantees structural soundness but also facilitates smoother operations and easier maintenance in the years to come.

Best Practices for Effective Communication in Steel Detailing Projects

Effective communication is paramount for successful steel detailing projects, especially in complex plant and warehouse structures. All project stakeholders—from architects and engineers to fabricators and site managers—must be aligned on specifications, design intent, and any changes throughout development. Regular, transparent meetings and clear documentation are essential practices. Detailed meeting minutes, email updates with relevant drawings (e.g., steel fabrication drawings), and centralized digital platforms for file sharing ensure everyone is on the same page.

Utilizing industry-standard software and platforms can streamline communication. Cloud-based design collaboration tools allow real-time access to the latest steel fabrication drawings, enabling quick feedback and decision-making. Additionally, establishing clear lines of responsibility and maintaining open lines between disciplines fosters a collaborative environment. This proactive approach minimizes errors, delays, and costly revisions, ultimately delivering high-quality, accurate steel detailing for plant and warehouse structures.

Industrial steel detailing is a critical aspect of constructing robust plant and warehouse structures. By leveraging precise steel fabrication drawings, professionals ensure accurate material cutting, forming, and assembly, leading to superior structural integrity. Effective communication and adherence to best practices throughout the detailing process are essential to avoid errors and delays, ultimately delivering high-quality, efficient facilities that stand the test of time. Steel fabrication drawings act as blueprints, guiding every step from design to completion, making them indispensable for successful industrial construction projects.