Steel detailing drafting is crucial for designing trusses and girders in large-scale projects, ensuring structural integrity and safety through precise dimensions, material selection, load analysis, and joining techniques. Advanced software tools and meticulous planning using CAD enhance visualization and accuracy, while robust quality control measures integrate into construction stages to meet industry standards.

“In the realm of large-scale construction, steel truss and girder systems play a pivotal role in shaping modern infrastructure. This article delves into the intricacies of steel detailing drafting for ambitious projects, exploring fundamental concepts and advanced techniques. From understanding basic truss and girder structures to navigating complex geometry, we uncover crucial design considerations ensuring structural integrity.

Through quality control measures, this guide highlights best practices for crafting robust systems, making it an indispensable resource for professionals in the field of steel construction.”

Understanding Steel Truss and Girder Basics

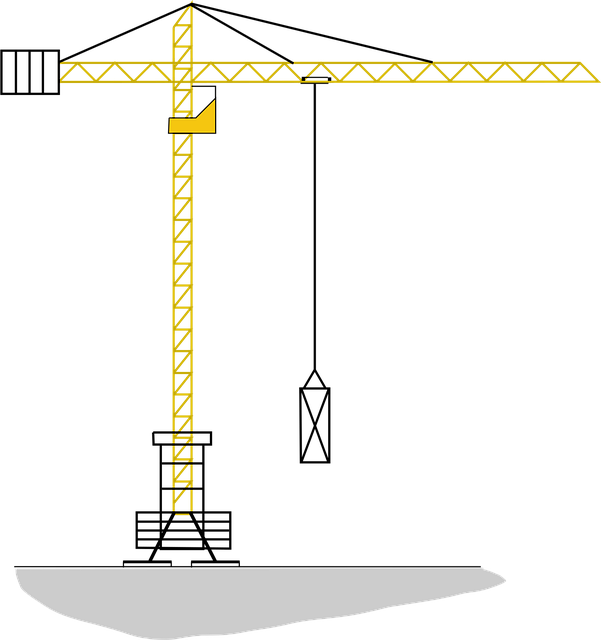

Steel trusses and girders are essential structural components in large-scale projects, offering unparalleled strength and stability. Understanding their basics is crucial for effective steel detailing drafting. A steel truss is a framework composed of straight members (typically bars or angles) connected by joints, forming a rigid structure that supports loads through tension and compression. Girders, on the other hand, are horizontal structural members designed to withstand significant axial loads, providing support to floors, roofs, or bridges.

Proper drafting involves meticulously detailing these components, considering factors like load capacity, span length, and material properties. Skilled drafters ensure precise dimensions, joint configurations, and connections to meet engineering specifications. This meticulous process is vital for the successful execution of any large-scale construction project, ensuring structural integrity and safety.

Detailed Design Considerations for Large Structures

When it comes to large-scale projects, meticulous attention to detail is paramount in steel truss and girder design. The intricate nature of these structures demands a comprehensive approach that seamlessly integrates structural integrity with aesthetic appeal. Detailed design considerations encompass not only dimensional accuracy in steel detailing drafting but also the careful selection of materials, advanced computational analysis for load bearing capacity, and innovative joining techniques to withstand extreme forces.

Effective steel detailing drafting is crucial for ensuring the longevity and safety of these monumental structures. Precise dimensions, well-documented specifications, and clear visual representations facilitate precise fabrication and meticulous assembly, minimizing errors and maximizing structural efficiency. By prioritizing these design considerations, engineers and architects can unlock the full potential of steel in crafting iconic landmarks that stand the test of time.

Drafting Techniques for Complex Geometries

In the realm of steel detailing drafting for large-scale projects, navigating complex geometries is a craft that demands precision and innovation. Advanced software tools have revolutionized how we approach these intricate designs, enabling engineers to create precise 3D models that accurately represent structural components like trusses and girders. This digital transformation facilitates better visualization, allowing stakeholders to grasp the intricacies of each component.

Effective steel detailing drafting involves a meticulous process where every angle, joint, and connection is carefully planned and documented. By leveraging powerful CAD (Computer-Aided Design) software, engineers can achieve unparalleled accuracy in detailing complex structures. This not only streamlines construction but also ensures safety by minimizing potential errors and enhancing the overall integrity of the project.

Ensuring Structural Integrity Through Quality Control

Maintaining structural integrity is paramount in large-scale projects featuring steel truss and girder systems. Quality control measures, integrated into every stage of the construction process, ensure that each component—from precision steel detailing drafting to final assembly—meets stringent industry standards and design specifications. This involves rigorous inspections, comprehensive non-destructive testing (NDT) techniques, and meticulous record-keeping to verify material properties, fabrication processes, and final structural performance.

Implementing robust quality control protocols not only safeguards against potential failures but also enhances the overall longevity and safety of these complex structures. It necessitates a collaborative effort between architects, engineers, fabricators, and construction teams, all working in harmony to deliver projects that stand tall against time, weathering forces of nature, and demanding loads while maintaining their structural integrity.

In large-scale projects, meticulous steel detailing drafting is paramount. By understanding the fundamentals of steel truss and girder design, considering intricate structural aspects, employing advanced drafting techniques for complex geometries, and upholding rigorous quality control, engineers can ensure the integrity and longevity of these remarkable structures. These practices not only optimize performance but also elevate the art of steel construction, setting new standards for the industry.